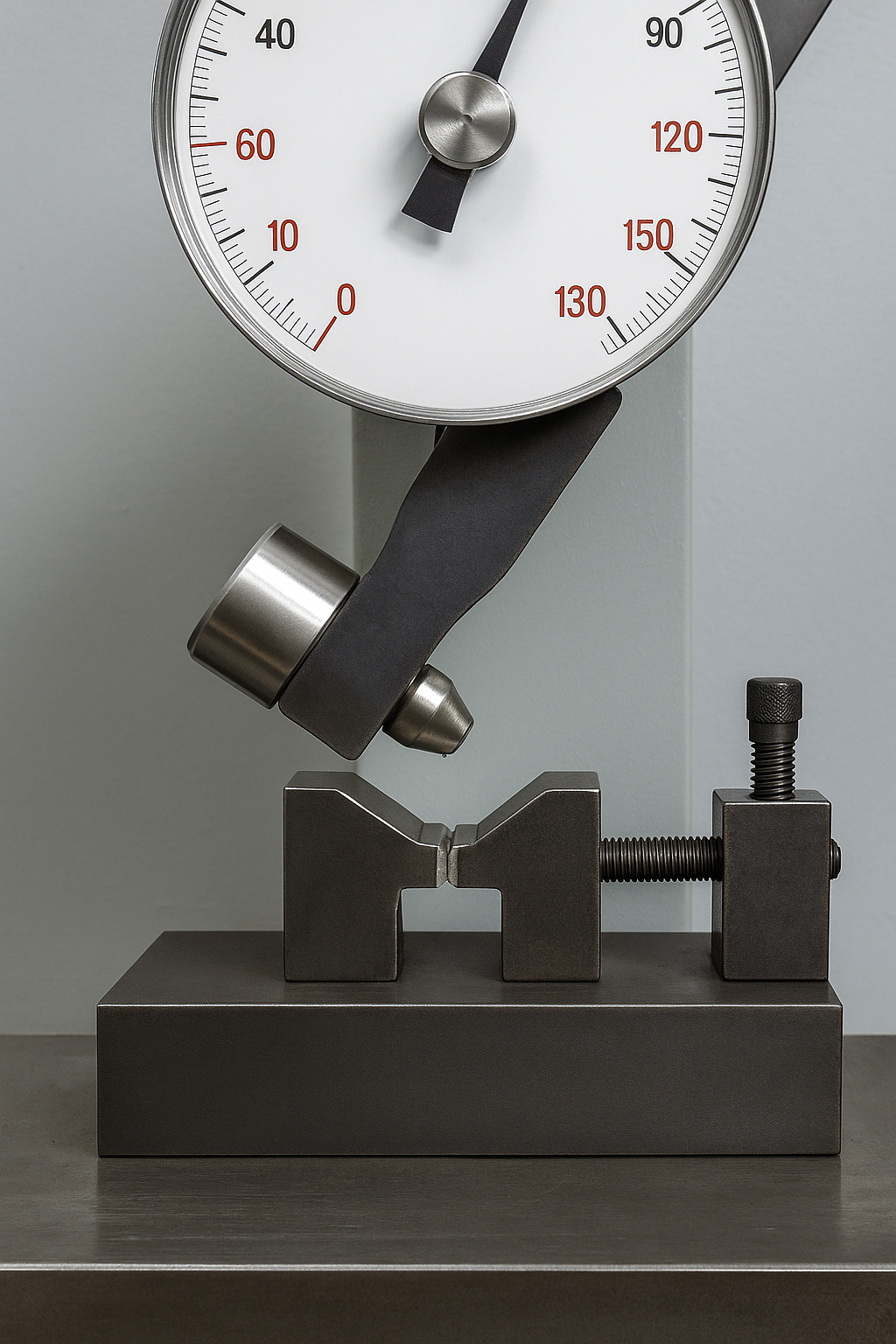

Charpy Impact Testing is a destructive mechanical test used to determine the toughness or impact strength of materials. The test measures the amount of energy absorbed by a notched specimen when fractured under high-velocity impact. This helps evaluate a material’s ability to resist sudden shocks and brittle failure.

Charpy Impact Testing is widely applied in:

• Weld procedure and welder qualification (PQR/WPQ)

• Assessing the ductile-to-brittle transition temperature of materials

• Evaluating structural steels, pressure vessel steels, and alloys

• Quality control in manufacturing and fabrication industries

• Ensuring compliance with ASME, ASTM, ISO, and other international standards

Test Specimens: Standard V-notch and U-notch specimens are prepared as per ASTM E23, ISO 148, or equivalent codes.

We provide accurate Charpy Impact Testing services with certified reports, ensuring reliable evaluation of material toughness for industries such as Oil & Gas, Power Generation, Manufacturing, Fabrication, and Construction sectors.

Enquiry