Liquid Penetrant Testing (LPT), also known as Dye Penetrant Inspection (DPI) or Penetrant Testing (PT), is a simple and cost-effective non-destructive testing (NDT) method used to detect surface-breaking defects in non-porous materials such as metals, plastics, and ceramics. The test is highly sensitive and can reveal even very fine cracks that may not be visible to the naked eye.

Applications of LPT:

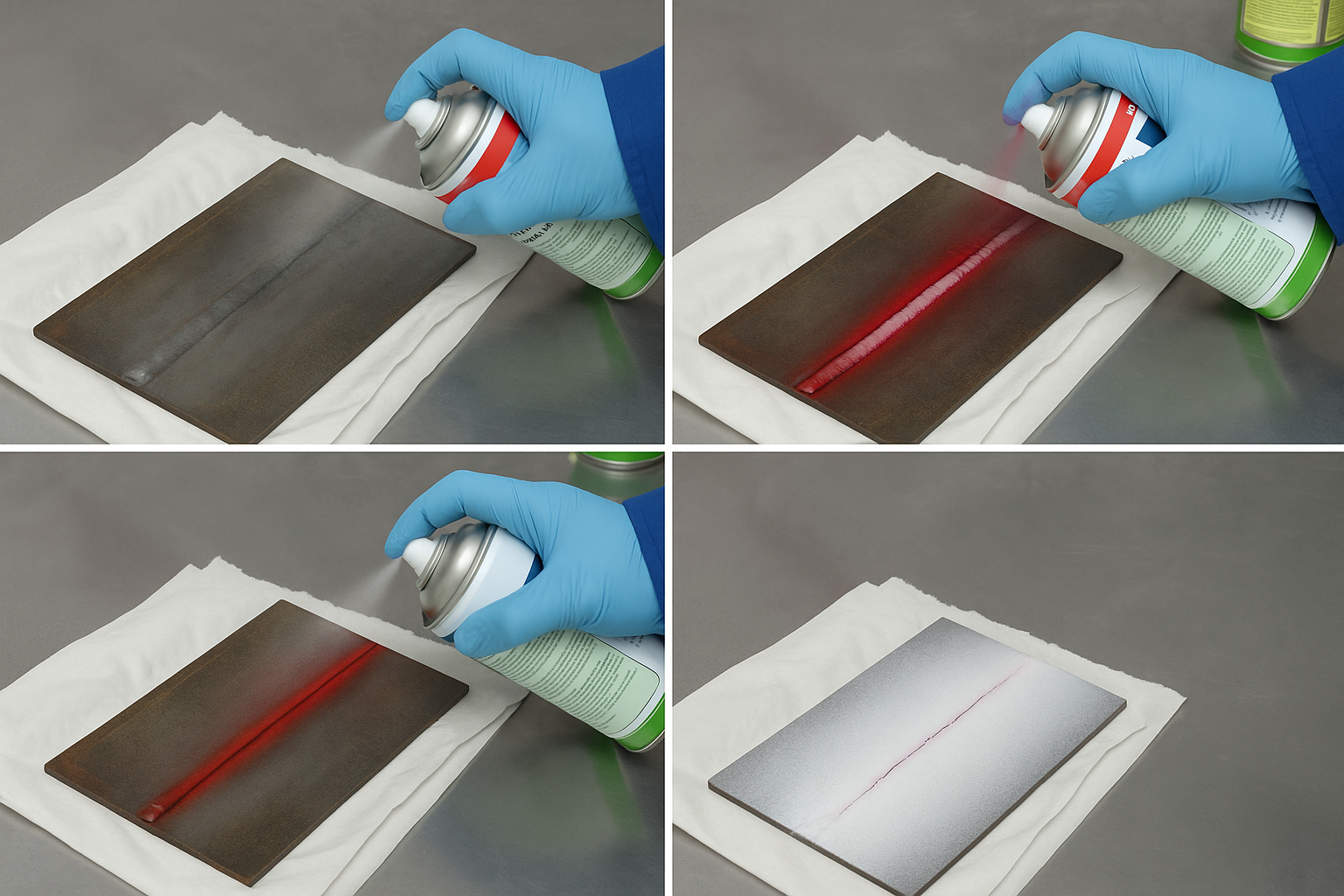

Steps in LPT: Surface cleaning → Application of penetrant → Dwell time → Excess penetrant removal → Application of developer → Inspection under visible or UV light.

Standards Followed: ASTM E1417, ISO 3452, ASME Boiler & Pressure Vessel Code

We provide reliable and accurate Liquid Penetrant Testing services with certified reports, ensuring quality and safety for industries such as Oil & Gas, Power Generation, Manufacturing, Fabrication, Automotive, Aerospace, and Construction.

Enquiry